Laser Cutting Systems,

are advanced manufacturing solutions developed to process different materials with high speed and precision. Offering repeatable and high-quality results on a wide range of materials such as metal, wood, plastic, fabric, acrylic, glass, and more, these systems play a critical role in modern production processes. Thanks to advanced laser technology, the thermal impact during cutting is kept under control; minimal deformation occurs on the material and clean, smooth edges are achieved.

Application Areas:

- Industrial Manufacturing: Precision cutting operations on metal and plastic parts.

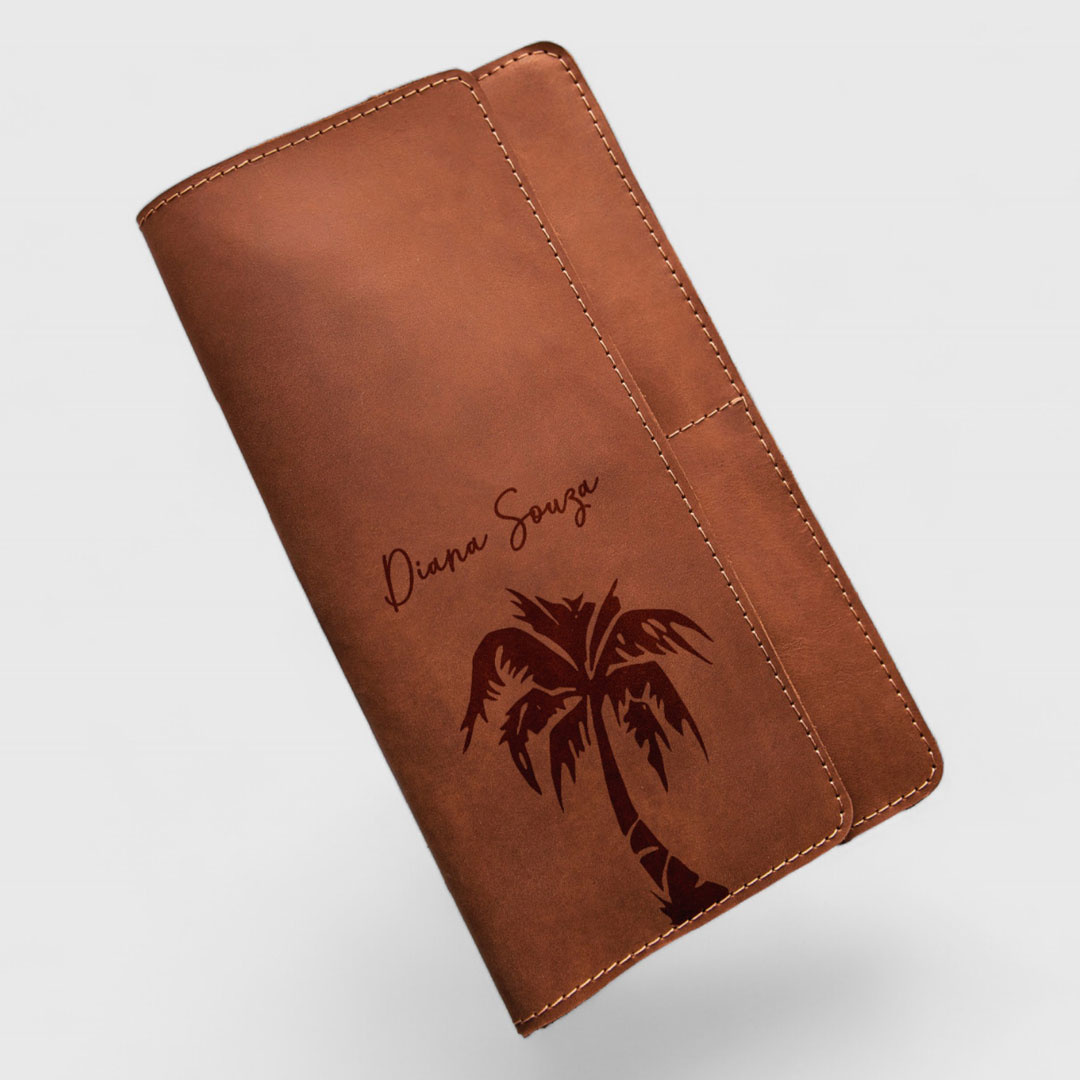

- Advertising and Design: Acrylic sheets, sign production, and decorative cutting applications.

- Architecture and Construction: Detailed and fast cutting operations on wood/metal panels.

- Fashion and Textiles: Detailed pattern and design cutting on fabric and leather.

- Electronics: Controlled processing on small-scale and precision components.

Laser cutting systems accelerate production flow while offering a high quality standard and cost advantages. Developed to meet industrial needs, these systems take your processes to the next level with stable performance, consistent cutting quality, and efficient operation. They are preferred as a reliable solution both for prototype work and for mass production.